Repipe Specialist Secrets: Leak Detection & Proactive Plumbing Design

Your plumbing system is the unseen backbone of your home—yet out of sight should never be out of mind. In Phoenix, where water chemistry is unforgiving, summer temperatures routinely top 110°F, and clay soils shift beneath concrete slabs, a single hidden drip can trigger a cascade of destructive events: mold colonizing wall cavities, joists softening beneath damp floors, or even subtle foundation heaving that permanently cracks tile and drywall. When a general plumber patches that visible leak, the relief is temporary; the true culprit—whether corroded pipe interiors, pinhole fractures in brittle plastic, or settling-induced joint stress—remains undetected, ready to strike again.

Repipe specialists operate on an entirely different level. They don’t merely react to today’s symptom; they hunt down every vulnerability in your water network, then rebuild and future-proof the entire system. Their secret weapons are advanced leak detection methods—tools and techniques that reveal concealed defects long before they manifest as leaks. Combined with a forward-looking, data-driven design approach, these diagnostics ensure your new piping network withstands decades of Phoenix’s harshest conditions.

Uncovering Every Hidden Leak

Most plumbers stop at the drip you can see or hear. A repipe specialist delves much deeper, employing multiple, complementary technologies to map the true health of your entire plumbing infrastructure:

Infrared Thermal Imaging

High-resolution thermal cameras scan every accessible wall, ceiling, and floor surface. Even a two-degree temperature difference betrays the presence of moisture wicking through drywall or seeping beneath tile. Early wet spots glow in stark contrast against dry substrates, allowing the specialist to pinpoint leaks days or weeks before mold colonies become established or structural materials degrade.

Acoustic Leak Detection

Sophisticated listening devices transform walls, floors, and ground into giant sonar arrays. Contact microphones clamp onto metal or plastic pipes, while probe heads rest against concrete slabs. Technicians “tune in” to the unique high-frequency hiss of pressurized water escaping narrow fractures. This technique locates hidden slab leaks or behind-wall drips to within inches—no jackhammers, no unnecessary demolition.

Pressure-Decay Testing

Your home’s plumbing network is intelligently sectioned into manageable zones—kitchens, bathrooms, laundry, outdoor spigots. Each zone is isolated with temporary test plugs, pressurized to standard municipal levels, and monitored over a set interval. A loss of as little as 1–2 psi over fifteen minutes signals a micro-leak, guiding the specialist to replace or reinforce the affected run before visible damage occurs.

Video Pipeline Inspection

Even drain and sewer lines can conceal critical defects. Flexible push-rods fitted with high-definition CCTV cameras traverse every bend and drop, capturing real-time footage of corrosion, mineral scale buildup, root intrusion, or partial collapses. These recordings become part of a comprehensive service report, informing the repipe strategy to include targeted drain remediation alongside supply line replacement.

By layering these diagnostic modalities, repipe specialists don’t just react to the leak you call about—they chart every weakness in your plumbing, replacing the entire compromised network rather than chasing one symptom at a time. The result is a water system reborn: leak‐proof, mold‐resistant, and engineered to perform flawlessly in the desert for decades to come.

Material Mastery: Selecting Pipes Engineered for Phoenix’s Extremes

In Phoenix, where municipal water regularly tests above 200 ppm hardness and summer temperatures routinely exceed 110 °F, your choice of piping material makes or breaks a repipe’s longevity and performance. A repipe specialist begins by mapping your home’s water profile—collecting samples at outdoor hose bibs, kitchen sinks, and laundry faucets to measure calcium, magnesium, pH, and chloride levels. This granular mineral analysis drives every material decision, ensuring your new system resists scale, corrosion, and thermal stress.

PEX (Cross-Linked Polyethylene)

- Engineered Scale Resistance: High-grade PEX formulations undergo cross-linking processes that smooth polymer chains, preventing calcium and magnesium crystallization. In field tests, scale-resistant PEX retained over 95 % of its inner diameter after simulated hard-water flushing equivalent to 20 years of use.

- Thermal Expansion Capacity: PEX expands up to 8 % under severe heat without developing microfractures—crucial when attic-mounted lines see rapid day-to-night swings from 140 °F to 70 °F. This elasticity virtually eliminates burst risks in freeze-thaw events or solar heat spikes.

- Installation Efficiency: With bend radii as little as five times the pipe diameter, PEX runs reduce elbow and tee counts by up to 60 %. Fewer fittings translate directly into fewer potential leak paths and faster labor times, cutting overall project costs.

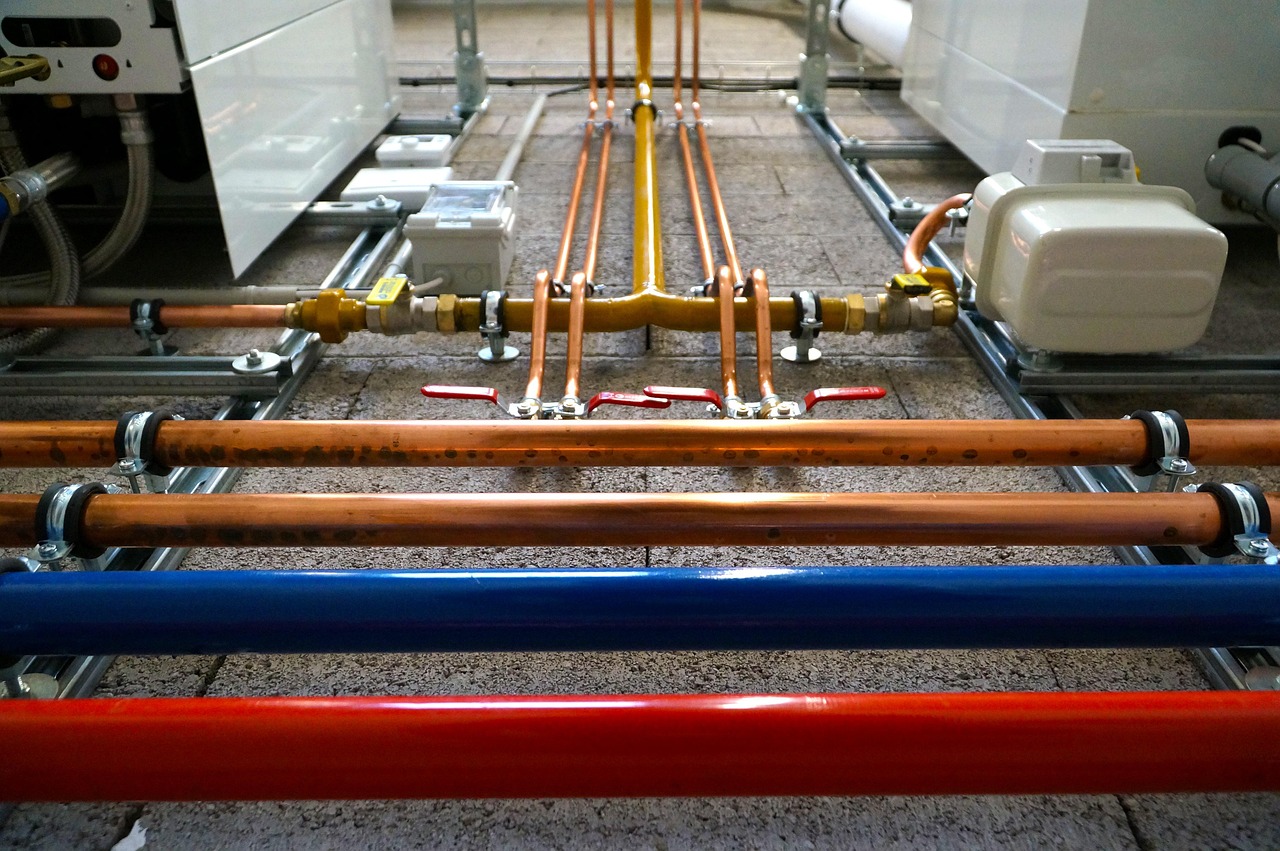

High-Purity Copper (Type L or K)

- Natural Antimicrobial Action: Copper ions inhibit biofilm formation, protecting hot-water loops where bacterial growth thrives. Independent studies show copper piping reduces microbial counts by 85 % compared to plastic under identical conditions.

- Half-Century Durability: Well-installed Type K copper can last 50 – 80 years even in soils with moderate chloride content. Its rigid structure resists rodent damage and external loads, ideal for semi-exposed garage or attic runs.

- UV & Heat Tolerance: Unlike many plastics, copper sustains its mechanical integrity at surface temperatures above 150 °F—critical for pipes routed through unconditioned spaces under desert sun.

Stainless-Steel & Brass Transition Fittings

- Galvanic Corrosion Prevention: When joining copper to galvanized steel remnants or steel shut-off valves, specialists employ stainless-steel dielectric unions and high-precision brass couplings. These fittings isolate dissimilar metals, preventing electrical current pathways that accelerate corrosion.

- Precision Machining & Sealing: High-tolerance threading and O-ring seals ensure zero-leak connections, backed by the repipe specialist’s quality-control protocols, including torque-verification and thread-sealant inspections.

By marrying detailed water-chemistry data with material science, repipe specialists craft bespoke piping networks that shrug off Phoenix’s toughest water and climate stresses—ensuring decades of clear, powerful flow without scale, leaks, or microbial concerns.

Proactive Plumbing Design: Architecting a Resilient Network

A repipe specialist moves beyond simple repairs to engineer your plumbing as a high-performance infrastructure. Their design philosophy rests on three pillars—distribution efficiency, seamless maintenance access, and dynamic pressure-temperature control—transforming reactive patching into future-proof architecture.

Optimized Flow Distribution

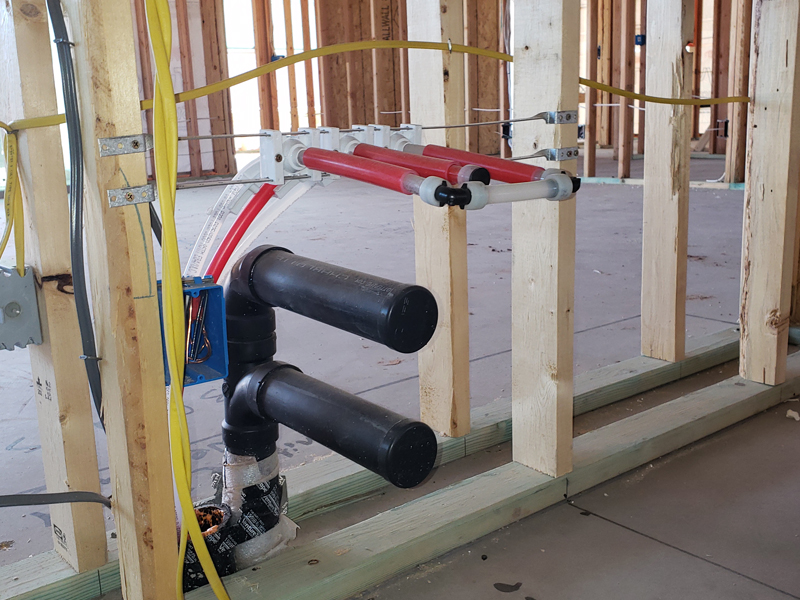

- Manifold “Home-Run” Layout: Each fixture (sinks, showers, toilets) gets its own dedicated line from a central manifold—eliminating the cumulative pressure drops inherent in traditional branching. With manifold systems, a simultaneous run of multiple fixtures doesn’t compromise pressure at any outlet, delivering consistent flows even during peak demand.

- Loop vs. Branch-and-Loop Hybridization: For large estates or multi-unit dwellings, specialists combine continuous looped circuits—where water circulates back to the manifold for uniform temperature retention—with branch-and-loop “trunks” that minimize redundant piping. This hybrid approach balances material efficiency with performance reliability.

Built-In Accessibility & Maintenance

- Strategic Valve Placement: Shut-off valves are installed at every sink, lavatory, shower, and appliance. This grid of local isolation points empowers homeowners and technicians to service any fixture without interrupting water to the rest of the house—reducing downtime and avoiding emergency water shut-offs.

- Cleanouts & Access Panels: Every major change of direction in drain lines is paired with a cleanout port, while hidden junctions behind drywall receive flush-mounted access panels. These features transform formerly invasive future inspections or repairs into simple, non-destructive procedures.

Thermal & Pressure Management

- Point-of-Use Recirculation Loops: Specialists integrate insulated recirculation lines with smart pumps and thermostats at distant fixtures. Homeowners enjoy near-instant hot water, slashing wasted gallons and reducing thermal stress on primary water heaters and piping.

- Zoned Pressure Regulation: In two-story homes or sprawling properties, the system divides into discrete pressure zones, each governed by a dedicated regulator or booster pump. This zoned approach delivers balanced pressure—from basement laundry rooms to attic bathrooms—while minimizing noise, water hammer, and undue joint stress.

By applying these proactive design strategies, repipe specialists create plumbing networks that operate at peak efficiency from day one—delivering spotless, high-volume flows, simplified maintenance, and adaptability for future expansions or smart-home integrations. Your repipe becomes not merely a repair, but a strategic upgrade that raises the bar on performance and peace of mind.

Surgical Installation & Flawless Restoration

When decades of hidden leaks and corroded pipes are at stake, repipe specialists deploy precision techniques that preserve your home’s integrity. They execute every step with surgical accuracy, combining targeted access, environmental safeguards, and turnkey restoration to deliver a seamless experience.

1. Precision Access Without Chaos

- Custom Panel Doors

- Installed behind cabinetry and in closets, these magnetic or flush‐mounted doors grant instant entry to entire pipe runs.

- Technicians map the network first, ensuring each panel aligns exactly with existing joists or studs, so there’s zero guesswork.

- Core‐Drilled Subfloor Ports

- Using diamond‐tipped bits, specialists drill 4–6″ holes through concrete slabs in non‐structural zones.

- This method avoids expansive trenching and protects tile, grout lines, and foundation integrity.

- Selective Ceiling & Wall Openings

- Small, strategically placed access panels in attic spaces or behind wall-mounted fixtures allow full repipe coverage.

- Panels are dimensioned to the minimum size needed, reducing demolition and preserving architectural details

2. Protecting Your Home Environment

- Layered Surface Protection

- Multi-layer drop cloths, floor runners, and adhesive film shield hardwood, tile, and carpet.

- Furniture is wrapped or relocated to safe zones under clear communication protocols.

- Continuous Air Quality Monitoring

- Portable air scrubbers with HEPA filtration cycle the work area air every 5–10 minutes.

- Real-time particle counters ensure airborne debris remains below breathing-level thresholds.

3. One‐Pass, Turnkey Restoration

- Drywall & Texture Mastery

- After piping is installed and pressure-tested, artisan drywall crews restore panels with exact texture matches—whether orange-peel, knockdown, or custom Venetian finishes.

- Joints are feathered with joint compounds that shrink minimally, ensuring no telltale seams or bulges.

- Precision Painting & Trim Reinstallation

- Color-matched primer and paint are applied using sprayers and rollers to achieve uniform coverage.

- Baseboards and crown molding are reinstalled with mitered corners so tight that even a 4× magnifier shows no gaps.

- Final Deep Cleaning

- Industrial-grade microfiber tools and backpack vacuums remove all settled dust.

- Technicians perform a multi-point walkthrough, wiping surfaces and inspecting finishes under daylight-equivalent lighting to confirm zero residue.

Smart Monitoring & Ongoing Peace of Mind

A repipe specialist’s job extends beyond installation. By embedding intelligent sensors and establishing preventive maintenance routines, they transform your plumbing into a self-protecting system.

1. Embedded Leak Detection Technologies

- Flow-Interruption Sensors

- Mounted at central manifolds and high-risk branches, these sensors establish a baseline “normal flow” profile for each zone.

- Real-time analysis flags deviations as small as 0.1 gallons per minute, triggering immediate alerts before water damage begins.

- Pressure Transducer Arrays

- Installed at service entry and each major zone, these transducers log pressure every second.

- A proprietary analytics engine detects patterns—such as slow pressure decay or rapid spikes—indicating latent weaknesses or impending valve failures.

- Integration with Home Networks

- All sensor data streams into a secure cloud platform accessible via smartphone app or web dashboard.

- Homeowners receive push notifications and can view live graphs of flow and pressure metrics, keeping them informed even while traveling.

2. Automated Emergency Safeguards

- Motorized Shutoff Valves

- When a major breach is detected, these valves instantly isolate the compromised zone, limiting water loss to under one gallon per event.

- System logs record the exact time, duration, and location of the auto‐shutdown for technician diagnostics.

- Fail-Safe Redundancies

- Dual-valve configurations at each manifold ensure one valve’s mechanical failure cannot block a necessary zone.

- Battery backup systems guarantee valve operation even during power outages.

3. Scheduled Preventive Maintenance

- Annual Comprehensive Audits

- Specialists revisit your home yearly to recalibrate sensors, recalibrate regulators, and re-verify pressure and flow against original “as-built” benchmarks.

- Detailed condition reports highlight any component degradation—so you can budget proactively.

- Biannual Flow Verification

- Using calibrated flow meters, repipe specialists measure actual GPM at every fixture and compare it to municipal supply ratings, catching scale buildup or blockages early.

- Component Lifecycle Management

- Pressure regulators, sensor modules, and mechanical valves are maintained or replaced per manufacturer-recommended lifespans, ensuring zero unexpected breakdowns.

By combining surgical installation, precision environmental controls, and proactive intelligence, repipe specialists deliver not just a new plumbing network but a living, self-monitoring system. This paradigm shift from reactive repairs to proactive resilience gives Phoenix homeowners decades of worry-free water service—and unparalleled peace of mind.

The Long-Term Value of Specialist Repiping

Investing in a full-home repipe by a certified repipe specialist isn’t merely an expense—it’s a strategic decision that pays dividends for decades. Here’s how this comprehensive upgrade compounds value over time:

1. Significant Utility Savings

- Elimination of Hidden Water Losses: Studies show average homes lose between 10–20% of water to undetected leaks. A repipe specialist locates and replaces every corroded or compromised segment, instantly stopping this waste.

- Improved Hydraulic Efficiency: Smooth-bore PEX and clean copper lines maintain optimal flow, reducing pump and heater runtime by up to 15%. That translates to measurable cuts in both water and energy bills—often recouping a portion of the repipe cost within a few years.

- Smart Flow Control Integration: When paired with recirculation loops and pressure regulators, specialist repipes minimize water heater idle times and eliminate rush-hour pressure spikes, further trimming utility consumption.

2. Extended Appliance Lifespan

- Consistent, Corrosion-Free Water Supply: No more mineral scale fouling heat exchangers or clogging spray nozzles. By delivering pristine, scale-resistant water, modern piping preserves the efficiency and longevity of dishwashers, washing machines, and tankless water heaters.

- Stable Pressure Protects Seals and Valves: Fluctuating pressure stresses appliance fittings and internal seals. The balanced distribution achieved by manifold systems prevents these pressure shocks, reducing service calls and premature component failures.

3. Maximized Home Value

- Certified Whole-Home Repipes as a Selling Point: Realtor surveys indicate that homes with documented, under-warranty repipes command up to 5% higher sale prices—and sell 20% faster—than those with aging, patch-repaired systems.

- Elimination of Inspection Red Flags: Buyers and inspectors no longer balk at obsolete galvanized, polybutylene, or Kitec lines. Your home boasts a modern infrastructure, easily passing municipal and lender requirements without costly last-minute fixes.

4. Decades of Reliability

- Premium Materials Backed by Manufacturer Warranties: Top-tier PEX and copper systems feature warranties of 25–50 years on materials, plus labor guarantees from the repipe specialist.

- Embedded Monitoring for Early Issue Detection: Flow detectors, pressure sensors, and automated shutoff valves mean that even the smallest future leak triggers an alert—preventing a minor fault from escalating into a major repair.

- Predictable Maintenance vs. Reactive Emergencies: Scheduled preventive inspections replace surprise emergency service calls, allowing you to budget modest annual upkeep rather than unforeseen five-figure disasters.

Together, these benefits compound: lower bills, fewer repairs, higher resale value, and a plumbing system that remains robust and reliable long after the initial investment.

Together, these benefits compound: lower bills, fewer repairs, higher resale value, and a plumbing system that remains robust and reliable long after the initial investment.

Ready to Transform Your Home’s Plumbing? Partner with a Repipe Specialist Today

Don’t let another day of leaks, scale, and pressure woes erode your comfort, safety, and wallet. Arizona Integrity Plumbing stands ready to apply our specialist expertise to your home:

-

Schedule Your Comprehensive Leak Detection Survey

- Infrared, acoustic, and pressure-decay diagnostics pinpoint every hidden vulnerability—no guesswork, no missed threats.

-

Receive a Customized Repiping Blueprint

- Transparent material recommendations, manifold-based distribution designs, and a phased, no-obligation installation timeline tailored to your needs and budget.

-

Lock in Your Project Start Date

- Precise coordination with your remodel or maintenance schedule ensures you never gut the same wall twice—saving time, money, and frustration.

-

Experience Turnkey Plumbing Excellence

-

From surgical access and surgical restoration to embedded smart monitoring, our repipe specialists deliver a worry-free system built for Phoenix’s harshest demands.

-

Call 480-274-9662 or visit our Contact Page now to secure your home’s plumbing future. With Arizona Integrity Plumbing—your trusted repipe specialist—you’ll enjoy enduring water efficiency, rock-solid reliability, and the confidence that your system is engineered to last a lifetime.

Hi! How can i help you?

Hi! How can i help you?